If a system runs reliably, it is usually not altered. This is especially true for sensitive systems that few people fully understand.

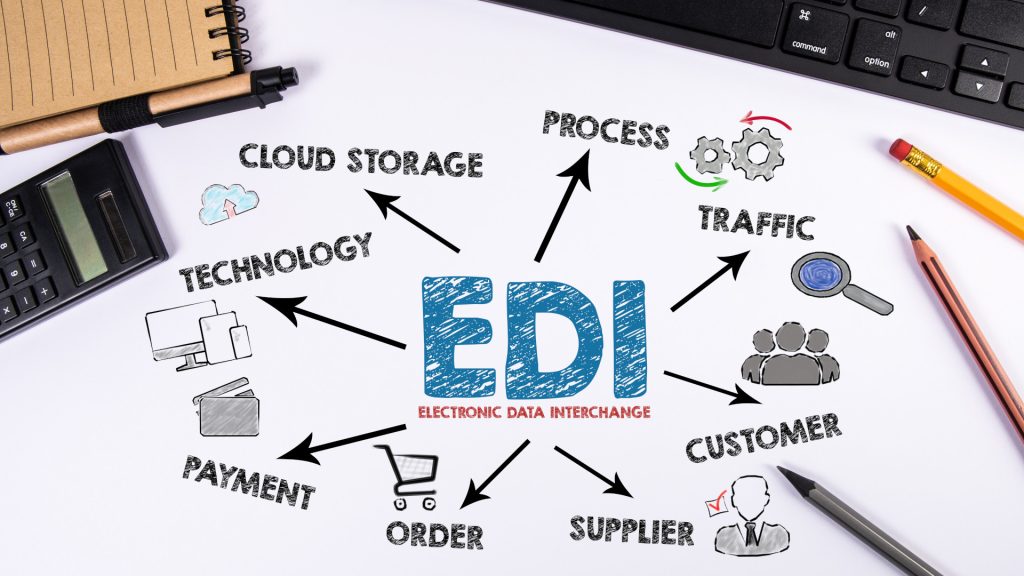

A prime example of this is electronic data interchange (EDI) in conjunction with SAP. But this can be risky

EDI is an important technology for the standardized, cross-company and automated exchange of business data. This includes orders, invoices, delivery advice notes and shipping notifications. These are transferred in a standardized format from the ERP system of one company to the system of another. SAP systems also exchange data automatically using EDI.

This form of data exchange is standard in the automotive industry. An industry that produces just in time and just in sequence cannot afford manual processes in which orders and time-critical documents are sent back and forth by email or fax. These would have to be recorded, processed and entered into the ERP system manually, which is too time-consuming and error-prone. This is why the automotive industry is a pioneer when it comes to EDI.

EDI is becoming the standard in many industries. However, the automotive industry would not be the automotive industry if it did not have its own extensive requirements for SAP and EDI, which are far more complex than in other sectors. In addition to the specifications of JIT/JIS production, there are strict regulations for quality management and the complete traceability of every single part. Even the packing of a pallet is specified down to the smallest detail.

Special requirements of automotive logistics

The data required for this must not only be mapped in the supplier’s SAP system, but must also be reliably transmitted to the OEM via EDI and correspond to reality on a one-to-one basis. The containers in which automotive plants receive parts are largely standardized. They are mainly plastic containers, either small load carriers (KLT) or large load carriers (GLT). These are delivered on complete pallets, sometimes in individual layers so that they can be stacked. However, not every container on a pallet is necessarily filled.

In automotive production, it is common practice to store the exact content of each KLT in the ERP system, including its assignment to the respective pallet. Empty KLTs are recorded in the same way. The size, volume and weight of each pallet are also included in the data records.

Keeping track of this wealth of information manually and transmitting it without errors is impossible. A transposed number, a slipped line or an incorrect delivery date always creeps in. Automotive manufacturers hold their suppliers liable for this, which can be very costly. Exchanging ERP data via EDI minimizes the susceptibility to errors and thus penalties. Apart from that, most OEMs require EDI connectivity from their suppliers.

EDI customization – who dares?

Most automotive suppliers in Germany are medium-sized companies. Very few of them have large IT departments that can map new requirements well – in contrast to Tier 1 suppliers. They do have SAP and also use EDI. But they often use on-premises-based legacy systems that were once set up but never touched again. There is also often a lack of sound documentation for the systems. In these companies, there are one or two experts who have set up these systems, have specialist knowledge and are now gradually retiring.

EDI basically ensures that information from a field in SAP is automatically entered into the corresponding field at the target company. When adjustments need to be made in EDI, there is increasingly a lack of skilled employees who can make them. Mapping changes in the SAP system in EDI is difficult because EDI messages can be very complex.

In the automotive world, suppliers are integrated into a network, have suppliers themselves and several customers. Not every participant in this network uses SAP. There are also other ERP systems in use. This results in formal differences, such as file formats. EDI must take this different arrangement and nomenclature of fields into account and be able to map them for each system with which it exchanges data. Various changes are often requested by the OEM and the suppliers have to adopt them, which means effort but also the risk of a burden because they then have to adapt their EDI systems.

Migration to S/4HANA

Change is also forcing the widespread introduction of S/4HANA. Support for earlier versions of SAP is only guaranteed until 2027. The new cloud-based product will establish itself as the standard, including in the automotive industry. However, this is not just a new version of SAP, but a completely new product in terms of technology and functionality.

SAP S/4HANA is a faster, more stable system with a modern user interface and is designed to support ongoing business transformation, the integration of new technologies, the inclusion of AI and data analysis. Consequently, S/4HANA also uses different data models than previous versions. This has an impact on data exchange via EDI. In case of doubt, suppliers will have to make major adjustments to their EDI systems to ensure that the interaction with SAP S/4HANA works.

You can’t do it without help

Medium-sized suppliers lack the resources for this, especially if the only employees with EDI expertise leave the company. The logical step is to turn to specialists. Although there are SAP consultants who understand and can implement automotive-specific requirements, they often lack EDI expertise. Similarly, there are some EDI integrators with SAP experience – but they often have no specific automotive knowledge.

SMEs therefore need a digitalization partner with automotive, SAP and EDI expertise to support suppliers in this transformation process. This partner enables the company to manage and adapt the electronic data exchange when requirements change on the OEM side.

A forward-looking digitalization partner also helps you to think about your own supply chain and, for example, to implement WebEDI so that all call-offs and shipping notifications are available in one place for suppliers who do not master EDI. This ensures that data exchange along the supply chain continues to run reliably in the future.

Positioning for the future with migration

Medium-sized companies that have not yet introduced SAP S/4HANA and where EDI expertise lies dormant in only a few heads are well advised to seize the opportunity to build up comprehensive EDI expertise at the same time as migrating to S/4HANA, document it comprehensively and distribute it across many shoulders. As they are often entering uncharted territory with the migration, they need the help of digitization specialists. These specialists support the change process with IT and workflow expertise and thus make a valuable contribution to functioning supply chains – an important contribution to keeping your own company fit for the future and competitive in the long term.