Digitization in industry is no longer just a buzzword, but an essential strategy for increasing efficiency, reducing costs and increasing competitiveness.

However, many companies face the challenge that the process of digitization seems to be associated with high costs and the need for specialized IT personnel. However, there are already solutions that offer an easy path to Industry 4.0, even for small and medium-sized companies.

Software and training instead of expensive IT

The key to successful digitalization does not lie in the purchase of expensive IT systems, but in the selection of the right software that is specifically tailored to the needs of a company. Modern software solutions are often modular and scalable so that they can grow with the company and adapt to its needs.

In addition, the training of existing specialists plays a key role in the easy achievement of Industry 4.0. Instead of hiring new IT specialists, companies can train their existing employees to work effectively with the new software. This not only promotes job retention, but also strengthens internal know-how. “With many production lines in particular, existing skilled workers only need to pick up minor additional skills to increase their productivity.”

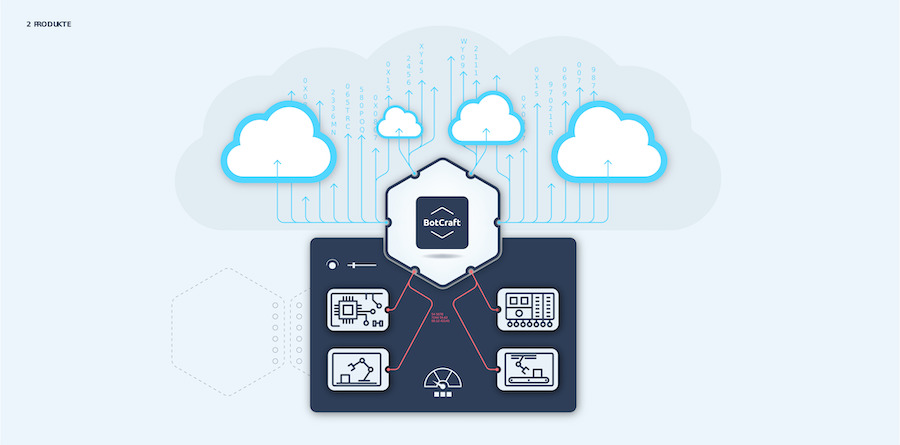

(Image source: BotCraft)

Increased productivity through monitoring and control

Because once successfully integrated, production processes can be designed more efficiently. Instead of one skilled worker operating one machine, the right software enables several machines to be monitored and controlled simultaneously. This leads to a significant increase in productivity without overloading skilled workers.

The monitoring and control functions, which are usually linked to such integration, also enable companies to quickly identify emerging bottlenecks, proactively plan maintenance and continuously optimize production processes.

BotCraft: Integration of bots in production lines

To gain a deeper insight into the practical implementation, Dr. Daniel Carton, who develops software modules and small bots on production lines himself with his company BotCraft, reports on this business opportunity. “Digitalization in the production environment goes far beyond the automation of simple tasks,” explains Carton. “By using smart software, skilled workers can now monitor and control multiple processes simultaneously. This not only increases efficiency, but also enables more flexible and adaptable production. Without having to increase the number of staff. In particular, an extra IT department is not required. An investment that can otherwise cost companies six-figure sums.

Industry 4.0 must be available to everyone in order not to lose touch. It also opens up new opportunities for all skilled workers, who are not replaced by technology but can broaden their horizons. Basically, the software becomes a supporter of the company and the skilled worker. Far too often, however, it is still demonized as a danger. Yet it preserves jobs instead of destroying them. Because if you can increase your productivity, you can reliably generate profits and thus provide an essential basis for keeping all existing team members employed. “

Companies like BotCraft prove that corporate digitization does not have to be associated with high investments, job anxiety or massive restructuring. By using the right software and training existing skilled workers, companies can increase their productivity, reduce costs and secure jobs at the same time. After all, the future of production lies in the intelligent integration of technology that enables skilled workers to take on higher-value and more efficient tasks.

(pd/Botcraft)